ACT Expo is a wrap: Photo gallery

The 2025 ACT Expo wrapped up after four dynamic days at the Anaheim Convention Centre in California. It attracted more than 11,500 attendees, including more than 2,200 registered fleets, nearly […]

The 2025 ACT Expo wrapped up after four dynamic days at the Anaheim Convention Centre in California. It attracted more than 11,500 attendees, including more than 2,200 registered fleets, nearly […]

I’m Corey and I need a female, non smoker Co driver out of Orlando FL, All of Florida, or willing to relocate to Florida. Text me for more details 216 849 8508

Joloda Hydraroll has installed an automated air cargo handling system for Schiphol Express at Amsterdam Schiphol Airport to make trailer loading and unloading faster and more efficient. It is one of the first major installations under the new Joloda Air Cargo Equipment division, which launched in 2024.

Schiphol Express provides comprehensive logistics services, including cargo handling, temporary ULD storage, sorting, and transportation for freight forwarders, airlines, and logistics providers.

Operating from Schiphol and Eindhoven Airports, the company manages the entire logistics process, from loading and unloading goods in first-line warehouses to transportation and delivery across the Netherlands. To handle increasing volumes, Schiphol Express needed a more efficient and reliable solution that would speed up trailer cargo transfer between its trucks and warehouses.

Schiphol Express’s existing equipment was outdated and needed replacing with a modern version featuring the latest automated technology. The manual unloading of air cargo, such as ULDs and PMC pallets, was time-consuming and labour-intensive, resulting in long trailer turnaround times and high staffing costs. The company sought a system to streamline operations, reduce manual handling risks, and enhance overall efficiency when transferring air cargo between trailers and warehouses.

Joloda Hydraroll designed, manufactured, and installed a fully integrated system consisting of a 20-foot truck dock and two 10-foot powered rollerbed positions. The configuration enables Schiphol Express to prepare or unload a full truck load (four 10-foot positions) more efficiently.

• Truck Dock

The truck dock system features hydraulic height and sideways adjustment for precise truck-to-dock alignment. Its 20-foot height allows two 10-foot PMC pallets or one 20-foot pallet to be unloaded from the trailer simultaneously. Once the pallets reach the end of the truck dock, the operator hydraulically lowers the dock to align with the powered rollerbed system. The truck dock is also specified with a winch, enabling the towing of air cargo from trailers in cases where pallets become stuck, even if the trailer is fitted with pneumatic rollertrack, modular rollerbed systems, or powered cargo rollers. Since all air freight trailers are equipped with rollerbeds as a minimum standard, the winch serves as a backup to ensure smooth operations. Additionally, trailer detection is integrated into the truck dock. The system automatically detects when a trailer is correctly aligned and ready to receive freight, further improving efficiency and safety.

• Powered Rollerbed

The powered rollerbed system consists of two 10-foot rollerbed positions that functions in conjunction with the truck dock to ensure the entire system operates as one seamless unit. Once the dock is aligned with the powered rollerbed, their motorised rollers propel air cargo further into the warehouse, eliminating manual handling and accelerating the workflow. The system is also equipped with weighing scales, enabling air cargo to be weighed and labelled with a printed sticker before further processing. Automation plays a key role in making this a one-person operation. Photocell sensors automatically shut off the motors to prevent air cargo from being propelled beyond the length of the truck dock or powered rollerbed system, ensuring controlled and efficient cargo handling at all times.

The team at Schiphol Express has increased productivity and reduced operational costs since implementing the new air cargo handling system; automating the unloading process has reduced unloading times to just minutes per truckload. Operators have also noted a smoother workflow, and the ability to handle higher cargo volumes has improved service levels for clients. The robust construction ensures durability under high-demand conditions, while the modular design and seamless integration with existing logistics processes has further reinforced the effectiveness of the installation and the opportunity for future expansion as cargo volumes grow.

Christophe Darras, Manager Operators at Schiphol Express, commented: “The installation of the air cargo handling equipment has transformed our operations. The automated system has significantly reduced trailer loading and unloading times, improved workflow efficiency, and enhanced safety for our team. The equipment has integrated with our existing processes seamlessly, allowing us to handle higher cargo volumes with greater reliability. This investment will be instrumental in optimising our logistics capabilities and performance.”

similar news

The post Automated Air Cargo Handling at Schiphol appeared first on Logistics Business.

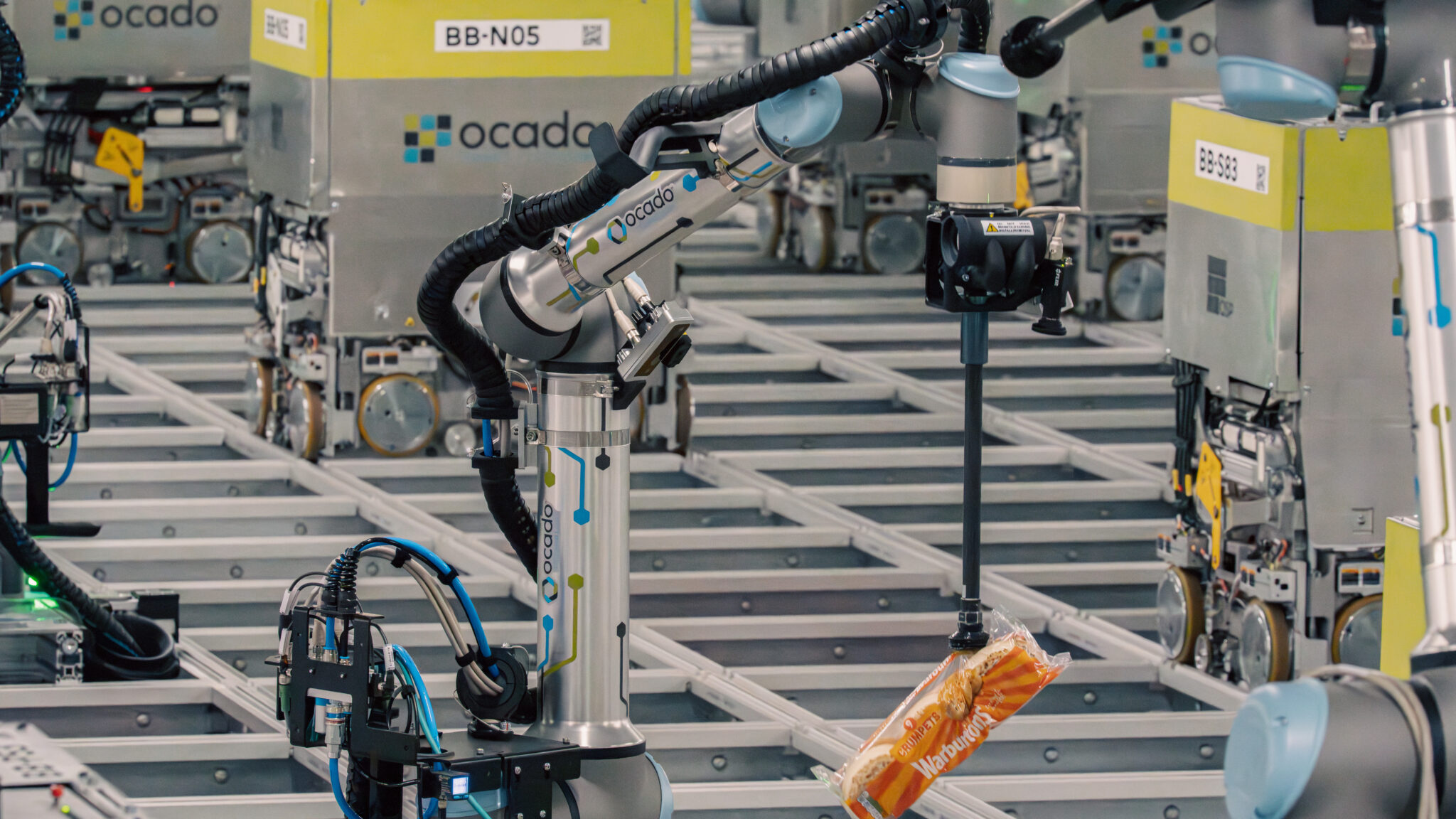

Automated picking and handling operations often require the usage of more than one technology in the robotic area. They should be both scalable and flexible. David Priestman got an update from a key player.

“We’re experts in the hardest area, which is individual item picking,” Ocado Intelligent Automation (OIA) CEO Mark Richardson told me when we caught up with each other at LogiMAT. Having seen the hive OSRS storage and retrieval system close-up myself it is impossible not to be highly impressed by it. With OIA firmly planting its flag in the global materials handling industry, exhibiting at both LogiMAT and ProMat, having both the right mix of products combined with the best route to market is the name of the game now.

As well as selling directly to non-grocery customers internationally OIA is going to leverage resellers to grow market share. The first deal announced, non-exclusively for the German-speaking market, was with Gebhardt Intralogistics Group. Gebhardt has a wide range of excellent handling and conveying systems, but not an ASRS. “We don’t have presence in Germany, so we’re looking forward to having access to a market that probably wouldn’t (readily) talk to us,” Richardson said. “It gives reassurance to customers that we have a presence. Gebhardt has a stellar reputation in the sector and across Europe, and we trust them to bring deep value and expertise to customers in the region. They have good mid-size capability.”

OIA is in discussion with a small number of other resellers internationally. “It was always our plan to use resellers,” Richardson added. “We’re picky about who.” He anticipates doing projects lead by and sold by Gebhardt (and other resellers) but also vice-versa, with OIA winning the business and taking the lead, utilising local installation, service and maintenance. Expect more announcements.

The company is extending the ‘Chuck’ range of AMRs to automate further processes. ‘Porter’ is a new AMR pallet-carrier that drives pallets point-to-point, all using the Chuck tech-stack. Porter picks, moves and places pallets directly from the floor with precision, even when they are aligned back-to-back. It recognizes its surroundings to safely handle and transport heavy loads autonomously and can be configured to handle cages, increasing flexibility and expanding fulfilment capabilities.

“Customers might buy just the Porter or Porter plus Chuck,” Richardson informed me. “In existing operations it can be used as an inexpensive pallet mover, collecting open or closed pallets and it can stack pallets immediately adjacent to each other, so there are no gaps. Porter takes us into the case handling and de-palletising robotics area, extending our product range. It will be used for inbound, from the dock door to the OSRS induct stations and loading into the grid – bringing the pallet to the decanter.”

Porter’s advanced vision system enables it to navigate safely and autonomously without requiring infrastructure changes or manual intervention. Moving at speeds of up to 4.5 miles per hour, the AMR dynamically adjusts its speed when detecting people or equipment in the area, ensuring workplace safety. Porter intelligently parallel parks itself in aisles to reduce congestion, keeping operations seamless for both robots and human associates.

Finally, I asked Richardson for an update on OSRS projects being delivered. Canadian pharmaceutical distributor McKesson’s installation will be finished this summer, ready for final testing and go-live. “We have a full pipeline,” Richardson stated, “as well as bidding for many projects.” Watch this space and listen to our Logistics Business Conversations Podcast with OIA on Spotify and other platforms.

The post Extending the Robotic Area appeared first on Logistics Business.

Penske associates across the organization will join today for Penske Pink Out – an associate-led breast cancer awareness event now celebrating its 10th year.

Maggie Seaman, National Account Manager – Northeast Region, whose mother passed away in 2017 from breast cancer, created Penske Pink Out to promote breast cancer education and to provide support to those battling the disease.

Penske Pink Out first began in 2015 with 200 associates in New Jersey and New York and has grown into a global movement.

Last year, more than 20,000 associates participated across Penske’s global footprint. Associates in Australia, Brazil, Canada, Indonesia, Mexico and the U.S. are expected to participate this year.

“I’ve seen a big shift in how we are open and communicating about breast cancer. Associates have embraced breast cancer awareness and demonstrated it is a very worthy cause,” Seaman said.

Penske Pink Out coincides with Breast Cancer Awareness Month, which seeks to bring attention to breast cancer and raise funds dedicated to finding a cure.

Breast cancer is the second most common cancer in women in Canada and the U.S. trailing only skin cancer.

In Canada, 30,500 Canadian women will be diagnosed with breast cancer, representing 25% of all new cancer cases in women in 2024, according to the Canadian Cancer Society.

Meanwhile, in the U.S. 1 in 8 women, or approximately 13% of the female population will develop breast cancer in their lifetime, according to the National Breast Cancer Foundation (NBCF).

In 2024, an estimated 310,720 women and 2,800 men will be diagnosed with invasive breast cancer, according to the NBCF.

In the weeks leading up to Penske Pink Out, associates held fundraisers, shared breast cancer information, and rallied around those who shared their connection to breast cancer.

Community service is an important part of the Penske Pink Out movement.

Nearly 200 associates in 15 states are participating in 24 American Cancer Society’s Making Strides Against Breast Cancer walks, which raises awareness and funds dedicated to research, 24/7 support for cancer patients and access to lifesaving screenings.

“Penske Associates, their families and friends that participate in their community at a Making Strides Against Breast Cancer event; whether it is forming team/joining a team, organizing fundraisers or volunteering on the event planning committee are at the heart of advancing the mission of the American Cancer Society (ACS) to improve the lives of cancer patients and their families,” said Stephanie McDonald, Director of Corporate Relations for the American Cancer Society.

“Their involvement allows ACS to fund research breakthroughs in cancer prevention, detection, treatment, and survivorship – and most notably, allows ACS to provide direct patient support to cancer patients and their families, whether it is providing a free ride to treatment or a free place to stay when they are traveling far from home for their cancer treatments,” McDonald said.

In addition, associates have also donated time to support the ACS’ Hope Lodge communities. The network of more than 30 lodges provides a free place to stay for people facing cancer and their caregivers when they travel to seek treatment.

Penske Pink Out could not have been as successful as it has been without the support of associates and leadership across the organization, Seaman said.

“Without leadership support, this would have never taken off in the first place. I think we have not only leadership at Corporate, but senior leaders and area leaders in the field who have embraced it, and it has been something they have encouraged their teams to support and to give back to the community,” Seaman said.

Follow Penske’s Facebook, Instagram and X pages to learn how our associates are marking #PenskePinkOut24.

Click the video below to learn more about Penske Pink Out and the associates who support it.

By Bernie Mixon

I want to sell my MC number 2013 very clean recorded still active and don’t know how much is it worth please help

WARNING: TAMERLANE EXPRESS INC IS A SCAM OPERATION – STAY AWAY**

Tamerlane Express Inc is not a legitimate trucking company — it’s a scam built to exploit drivers and owner-operators. They will **lie, cheat, and steal** every dollar they can from you.

Drivers often receive **nothing** for their hard work. Owner-operators are **ripped off**, hit with fake deductions, and **robbed of their rates (RATCON)**. Even if you haul loads worth **$10,000 a week**, you could end up **owing them…

WARNING: TAMERLANE EXPRESS INC IS A SCAM OPERATION – STAY AWAY**run by uzbekistan

Hello to Owner Operators and also those who are in upper management within trucking companies big and small.

I come to you to discuss and propose a unique idea that will benefit some new drivers, and the OO / companies that are open minded to working on this. It will provide the industry with additional drivers, those which would otherwise be unable to work many jobs, including driving OTR.

We have a devastating environmental health condition that seriously limits potential jobs (and…

Seeking OO or Truck Company for new method testing, increase recruitment potential in industry.

Does anybody have a PDF copy of the cheat sheet for the different kinds of hazmat that can be mixed and can’t be mixed. I’m looking for one that would format on a normal size sheet of paper so I can keep it in my binder a little easier. I purchased one and it won’t format right. The ones you buy don’t seem to come any smaller than the big sizes. Or if somebody has a good site, I’m willing to pay for it.

Thank you.